CASE STUDIES

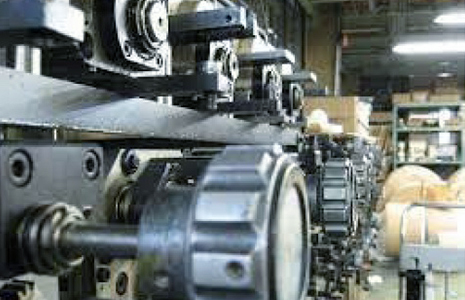

Printing / Inspection

Aiming for differentiation through printing operations that leverage the strengths of being an affiliated company

Implementing company:

Densanshi Co., Ltd.

Model:

UV Inkjet printing system SJ-N500

Inspection system iFocus-X & iFocus-Y

About Densanshi Co., Ltd.

Established as a business form printing company, we have a history of about half a century. In addition, we have a history of more than 20 years in data printing that adds value such as "QR codes and serial numbers" and "personal information such as addresses, customer barcodes, and maps" to spot products and direct mail for campaigns. I have. We are leading the industry with a wealth of experience and brilliant achievements cultivated during that time. CTC JAPAN will become an affiliated company of Densanshi Co., Ltd.

Reason for introducing CTC JAPAN inkjet printer

The impetus for introducing an inkjet printer was to handle the rapidly increasing printing business without increasing the number of workers. In the past, we were working with three flash fixing type laser beam printers, but one inkjet printer maintains higher productivity than three laser beam printers.

One of the attractions is that the operating cost is lower than that of laser beam printers. In the case of laser beam printers, in addition to maintenance contracts, many consumables such as toner, developer, and photosensitive drum were required, and these costs accounted for a large proportion of operating costs. Now we are freed from the management and storage of such consumables.

Advantages of introducing CTC JAPAN's inkjet printer and inspection machine

The best thing about installing CTC JAPAN's inkjet printer was being able to verify the print results. It is now possible to verify the printing of all records, such as whether there is faintness or dirt, even if it is only the fixed-length portion. The verifier newly developed by CTC JAPAN has fast software settings and can read even high-speed printing without delay. In addition to variable data verification, background inspection of fixed image parts is also possible, demonstrating great power in product quality assurance.

At the beginning of the introduction of inkjet, we used metal halide UV for drying, but recently changed to LED-UV light. After switching to LED, the ink dries and fixes better than before, power consumption has decreased, CO2 emissions and exhaust heat have decreased, and the work environment has improved. There were also unexpected effects. The print head and the light source for drying have become closer, resulting in improved print quality. This is especially true when using high-quality paper that easily bleeds. As an affiliated company of CTC JAPAN, we are involved in the printing business, so it is a great strength for us to take up our requests and apply them to product development.